PROMOTIONAL MERCHANDISE

PRINTING GUIDE

What Are The Most Popular Print Methods Used For Merchandise?

Once you have weighed the options and decided on what promotional merchandise your business will invest in, the next big decision is your printing method.

How you choose to print your logo and branding onto your item matters. It will determine the quality and longevity of the print, the design's complexity and the product's perceived value.

As experts in promotional products with many years of experience, we know which print methods work best for applying your logo and branding to our range of promotional gifts.

This comprehensive promotional print guide will clearly breakdown each printing technique and its benefits so that you can make an informed decision and achieve the best results.

Spot Colour Screen Printing

This is one of the most popular methods used in promotional print. It involves creating a stencil of a design on a mesh screen and then pushing the ink through this screen onto the desired area of the material. A different screen will be required for each colour, so the more complex and colourful your design is, the more costly this method can become. It is suitable for 4 spot colours.

Screen printing is extremely versatile, so it is the go-to option for many. It can be used to print on almost any material, including fabrics, wood, and paper. The only requirement is that the item has a small, flat surface area. This makes it a great option for printed t-shirts, custom notebooks, and many different types of promotional bags.

It also produces vibrant colours, and Pantone references can be used to match exact brand colours.

Spot Colour Pad Printing

Is pad printing the right option for your business?

Pad printing is a technique that involves the artwork being etched onto a printing plate where the ink is added. A rubber or silicone pad, or stamp, then picks up this ink and presses it onto the area where the ink is transferred.

This method is ideal for printing on more unusual shapes, such as promotional pens, custom stress balls, and branded electronic devices and gadgets such as printed power banks or custom cables, which is difficult with most other techniques. It also produces a quality finish with high resolution and detail, which makes it the best option for artwork with small text or intricate designs.

Direct Digital Print

Full Colour Dye Sublimation Printing

This printing method uses heat and pressure to transfer artwork that has been digitally printed onto a coated paper substrate with a special dye sublimation ink onto promotional products. The heat press turns the ink into a gas that permeates the surface of the material leaving behind a durable print.

Dye sublimation produces vivid colours and excellent image resolution, making great quality prints that increase the product's perceived value. It also gives a soft touch feel and a durable finish since the dyes are infused into the material rather than sitting on top of it. Great for full-colour promotional mugs, custom water bottles and promotional tote bags.

Laser Engraving

If you are branding onto metal promotional products, such as custom executive metal pens or company stainless steel metal bottles, then laser engraving is the most suitable technique.

For eco promotional products made out of wood, such as our eco-custom bamboo products, laser engraving can create stunning results.

It involves the design or artwork being uploaded into a laser engraving machine, emitting a laser beam that rapidly heats up and vaporises the surface it is hitting. The laser essentially draws out the artwork onto the metal item.

It’s a precise and long-lasting branding method that leaves a clean finish and produces a promotional product that looks elegant.

Popular Modern Branding Methods For Customising Clothing

Promotional clothing items are popular for branded merchandise, especially when attending events, such as merchandise gifts to sports fans and charity fundraising events.

They have their own specific printing techniques.

Machine Embroidery

This method is extremely common for branding clothing items. It requires a digital embroidery file containing the design being loaded into an embroidery machine. The fabric or material to be embroidered is secured in a hoop, which is then attached to the machine. The machine moves the hoop and the fabric in precise, programmed motions while a needle attached to the machine's arm stitches the design onto the fabric.

It’s an automated system in which the machine changes the thread colours and stitch types as specified in the file. This makes it an efficient method that creates colourful designs with accuracy.

Embroidery is great for custom baseball caps, custom workwear such as company polos, and branded jackets and logo fleeces

Printed Transfers

Printed transfers involve the design being printed onto a special transfer paper (as a mirror image to ensure correct orientation when transferred) using a digital printer. The transfer paper is then placed face down onto the fabric where heat and pressure are applied using a heat press machine transferring the ink onto the fabric.

The production times using printed transfers are quick making them ideal for tight deadlines and they offer versatility with intricate details and even gradients being able to be printed using this method. This is also a cost-effective solution for small quantities or one-off designs.

Full Colour Embroidery - New for 2024!

The process dyes the thread as it is being embroidered, which allows us to incorporate a gradient of colours.

The great thing is that it is sustainable, and we're able to match Pantones too

Contact our team for more information.

Alternative Merchandise Branding Methods Embraced In 2024

Many businesses are starting to move away from the traditional and more ‘standard’ printing techniques mentioned above to ensure that they are standing out from competitors. In 2024, the trend is shifting towards lesser-known or popular options to meet the specific printing needs of businesses and create promotional products that will make a real impact.

Resin Domed Stickers

This is where your design is digitally printed onto a plastic sticker sheet, and then a liquid resin is poured on top. As it is left to set, the resin levels out and forms a thick, clear dome over the printed surface, leaving a raised badge on the sticker.

The three-dimensional effect, glossy appearance and durability leave a premium feel over a standard paper sticker sheet. It’s a popular technique for promotional electronics and custom decal design for company golf umbrellas or even custom corporate metal pens to the tips

Self-adhesive Paper Stickers

These paper labels with an adhesive backing come on a roll or sheet where the design can be printed and each sticker peeled off and applied to various surfaces.

It’s as simple as it sounds which is why many businesses find it so appealing as an option for their merchandise. Once printed, the labels can be applied by the business itself making it a fast and cost-effective method.

Hot Foil Blocking

Hot foil blocking, or foil stamping, is when a roll of thin foil is placed between a heated metal die with the design engraved on its surface and the surface of the material. The heat and pressure of the application cause the foil to transfer and adhere to the substrate in the shape of the artwork on the metal die.

This leaves a shiny, metallic finish that is difficult to achieve with any other printing methods.

The main reason that this technique is a favourite is because its eye-catching result enhances the visual appeal of any product. It creates promotional products that stand out and have a more premium, luxurious look.

Most suitable for custom bookmarks, personalised company diaries and notebooks. Also popular for custom luggage tags and custom coasters

Embossing

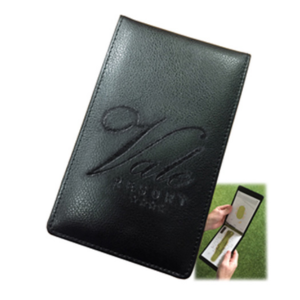

Embossing is a printing method that can be done with or without ink to achieve the finished look of a raised pattern or subtle, tactile effect.

It involves a metal plate with the artwork etched onto it, at which point the depth of the embossed or debossed area will be determined. The plate is then pressed onto the material with high pressure, causing the material to deform and take on the shape of the design. It creates either a raised (embossed) or recessed (debossed) pattern.

This is a method commonly used for custom notebooks and promotional leather goods, which take well to embossing and suit the more luxurious feel and look of this technique. There is also something quite appealing about embossed branded merchandise because of the interactive element, which makes them feel as nice as they look.

most suitable for custom executive mousemats, company coasters and custom golf scorecards or executive promotional notebooks.

Etching

There are two methods for etching, both of which achieve similar outcomes, but the more modern technique is considered more precise and has less of a negative environmental impact.

It involves a photosensitive material being applied to the surface and the design being transferred onto it using a UV light. A chemical solution is then used to dissolve away the unexposed areas leaving behind an intricate pattern.

In traditional etching, such as metal etching, a design is first transferred onto a material like metal using an acid-resistant material called a resist. The exposed areas of the metal are then chemically or electrochemically eroded, leaving behind the desired design.

Etching is a durable option for branding because it resists wear and fading and can withstand harsh chemicals. It’s best suited for printing onto metals, glass, ceramic and plastic.

This method is becoming more popular on etched promotional mugs and custom etched drinkware such as bottles and cups.

Call

Visit

Merchandise Ltd - Unit 9 Adler Industrial Estate, Betam Road, Hayes, Middlesex, UB3 1ST